Integrated Process

JingFong Group has always pursued the vertical integration of major processes and currently it is one of the exceptional that has the control of every phase of the production process within its structures, including the forging, the tools production, tapping, assembling, deform, the surface treatments of nuts, washing, sorting and the packaging processes.

Forging Process

In the factories of JingFong and Thailock, there are over 100 cold-forming lines with 4, 5 and 6 stations which are among the most modern on the market. In addition, embedded smart sensor & real-time device monitoring modules assisted in controlling process quality.

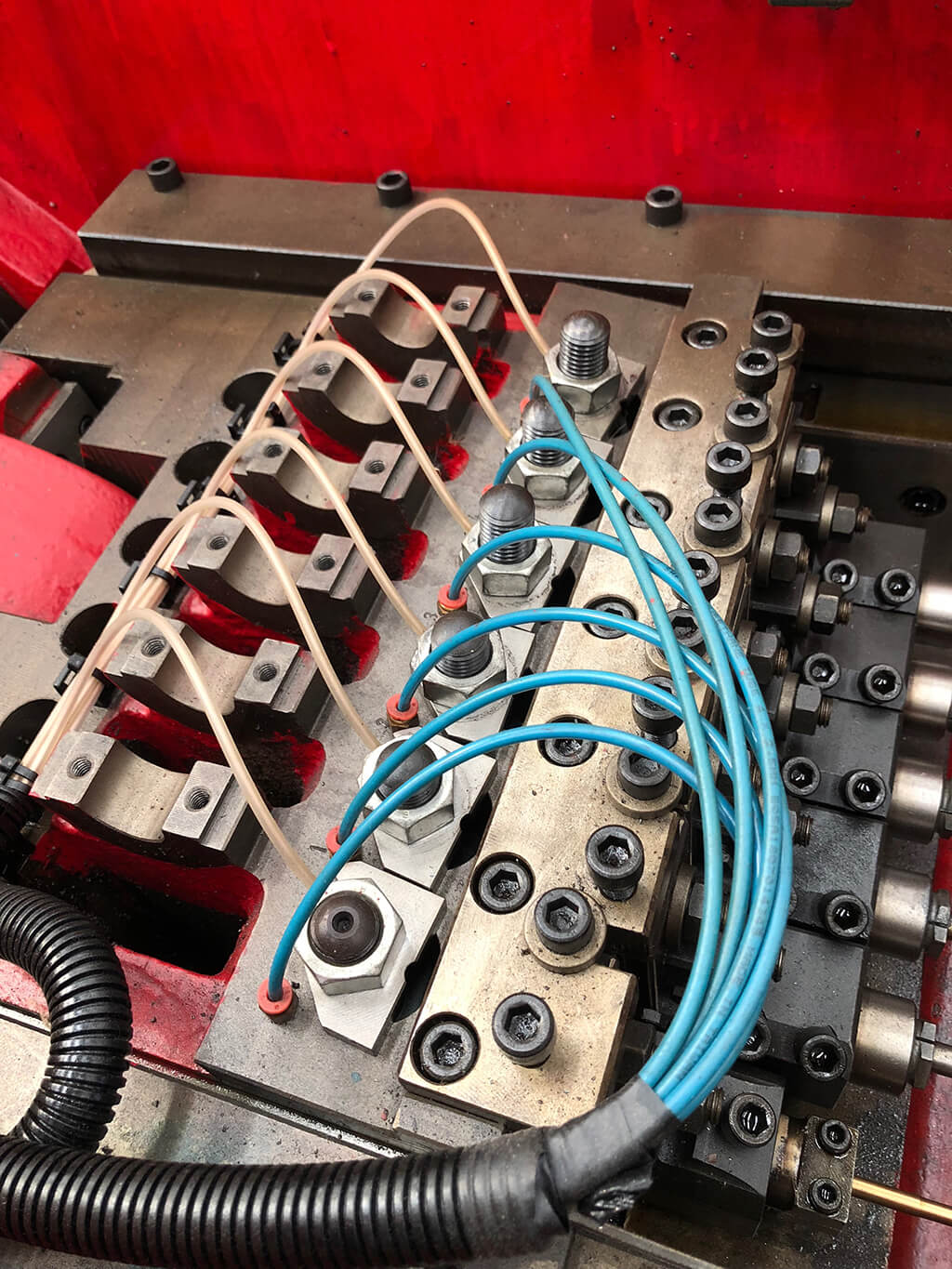

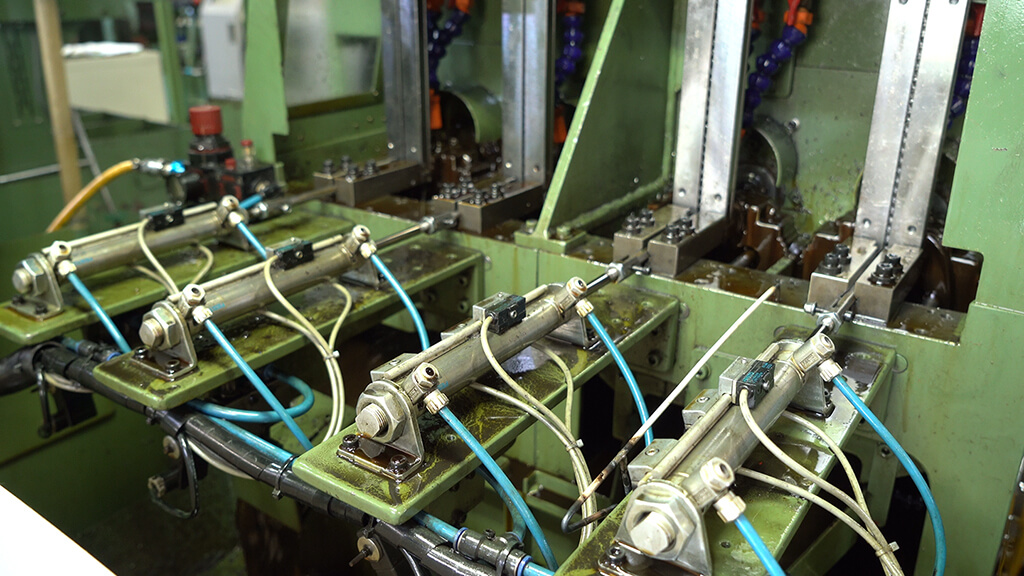

Tapping Process

Over 400 tapping machines in two factories, can manufacture all type of nuts over 3,000 tons/per year.

Assembling Process

One of key processes for prevailing torque type nut, by which all types of Nylon Insert Nuts account for over 50% of total production.

Deform Process

One of key processes for prevailing torque type nut, which can adjust the expected torque value with difference coefficient of stress force.

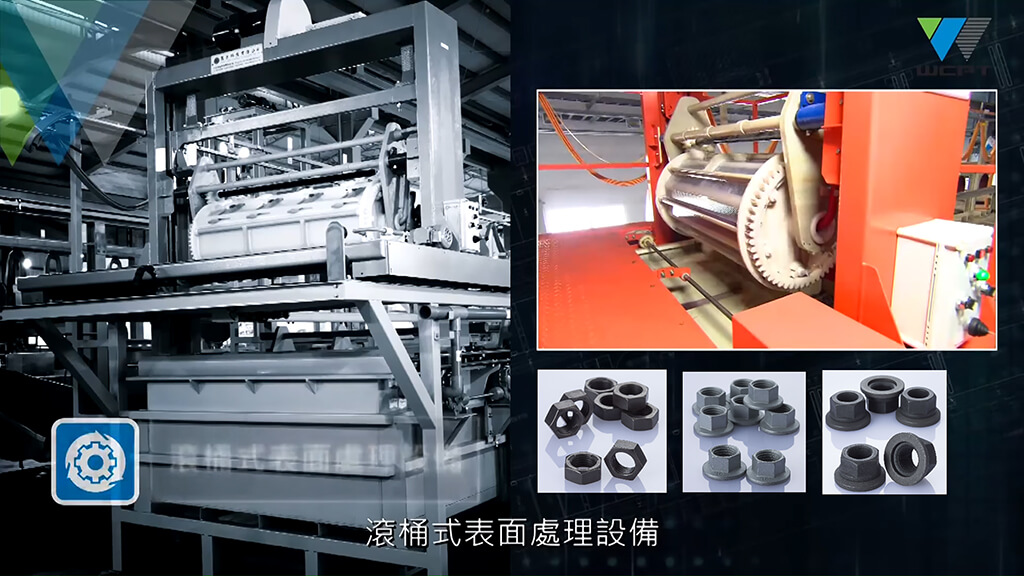

Surface Treatment: All New Zinc-Nickel Alloy Plating Process

Its strengthened protection against corrosion allows the fastener to be used on automobiles.

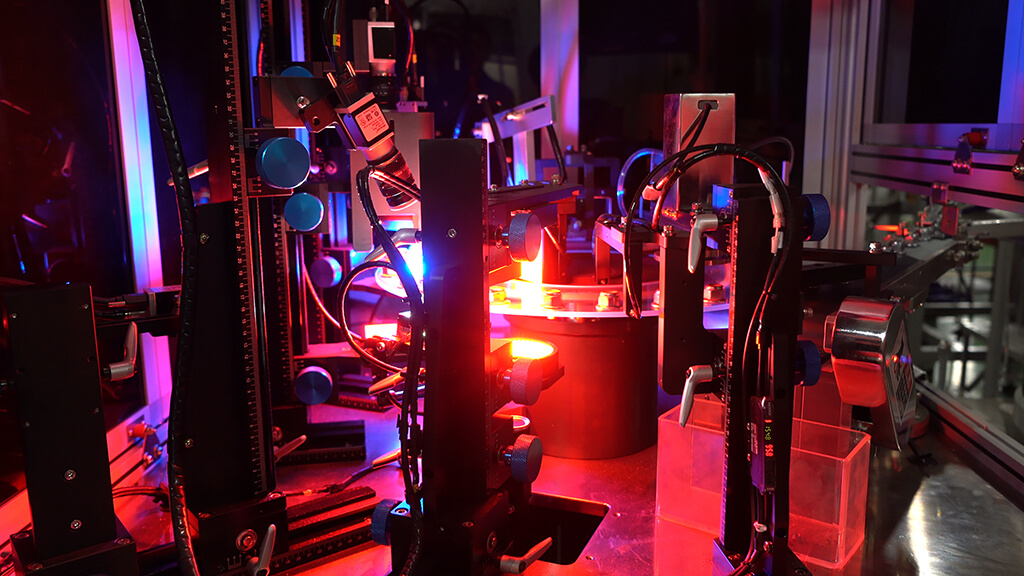

Sorting Process

We have constructed a large number of automatic lines, which are able to sort 300,000 pieces per day for critical applications in the automotive sector that require a defect level below 20 ppm.

Packaging Department

In the packaging department of JingFong plant there are 3 packaging lines capable of realizing any type of packaging requested by the customer.